BSI Registered to

EN9100:2018 / AS9100D & JISQ 9100:2016

/ ISO

9001:2015 / EN9104-001:2013

Based in Southend-on-Sea, we produce a wide range of components in ferrous and non-ferrous materials and it is our aim to provide the highest quality of service.

With substantial investment Protocon Engineering Limited is able to

offer a wide range of sub-contract, multi axis CNC machining services

and this latest technology provides customers with CNC Milling capability up to 30" in length, together with CNC turning facilities up to 50 mm in diameter barfed, and larger billet sizes.

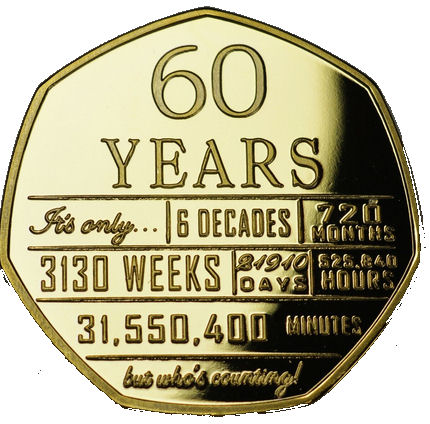

We are a family business (currently in its third generation), and we have been trading for over 59 years.

We continually invest in our

processes and facilities to meet the

changing requirements of the Aerospace sector, and offer

design input at the development stage, first article inspection reports, and full traceability on all of our parts.

We currently produce components

for

the aerospace, communications,

electronics and medical industries. Parts are currently produced for

Airbus A320 and A380, Boeing 777, 787, and C17, Eurofighter, F16, F22 and several helicopter projects.

These components are used in

the

following

Fuel Management Systems

Fly by wire pilot controllers

Actuators and Relays

Endoscopes and fibrescopes

Telecoms devices

Pilot seats and aircraft galley equipment